DIY

DIY is the best way to create the perfect piece of art, furniture, and projects you need for your home & garden. We have you covered, from DIY to furniture, decor, and home decor. We bring you the latest trends in all shopping categories—making every DIY crafting project easy and fun! We want to ensure that our readers have the latest and greatest resources to help put their ideas into action.

- 15 DIY Day Of The Dead Costume Ideas

- 12 Creative DIY Welcome Sign Ideas

- 20 Easy And Fun DIY Dinosaur costume Ideas

- 12 Cute DIY Yoshi Costume Ideas To Make A Fun

- 14 DIY Wire Holder Ideas For Soldering

- 14 Cheap DIY Pool Ladder Projects For Garden

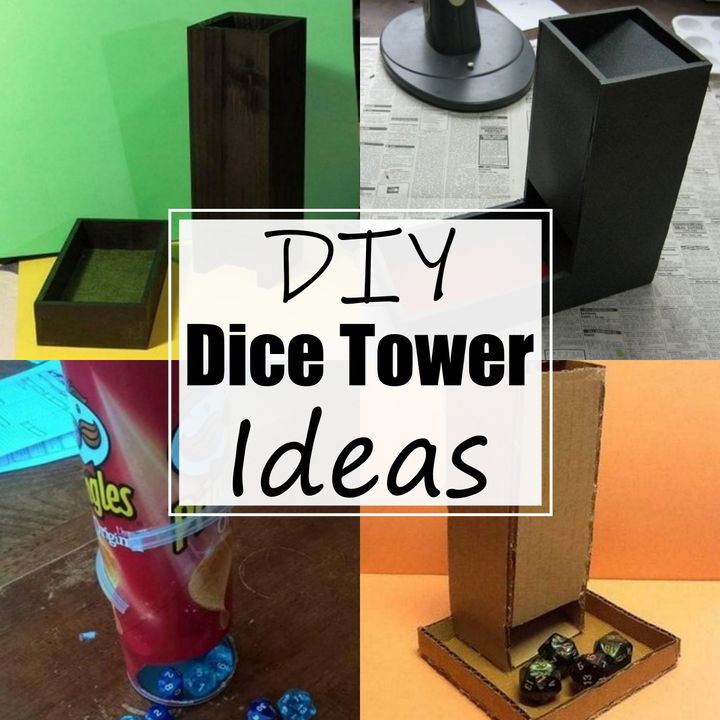

- 10 DIY Dice Tower Ideas To Inspire

- 12 DIY Above Ground Pool Ideas On A Budget

- 18 DIY Pool Cover Ideas For Safety

- 27 DIY Coat Rack Ideas For Small Spaces

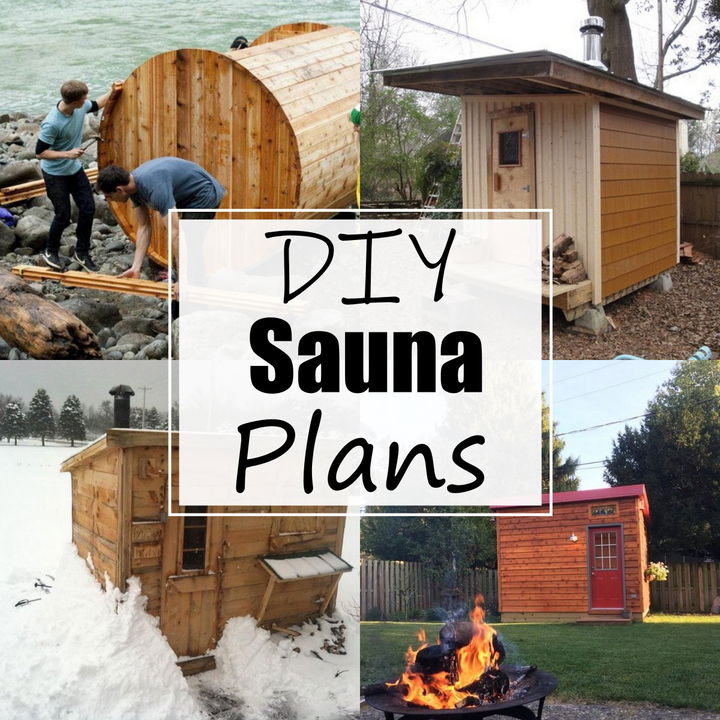

- 25 DIY Sauna Plans For Steam Baths

- 27 DIY Play Kitchen Ideas For Kids To Learn

- 27 DIY Dice Bag Ideas And Pattern Free

- 23 DIY Kiln Ideas For Home Use

- 15 DIY Inground Pool Ideas For Any Site

- 24 DIY Mudroom Storage Ideas For Small Spaces

- 20 DIY Storage Cart Plans For Your Home

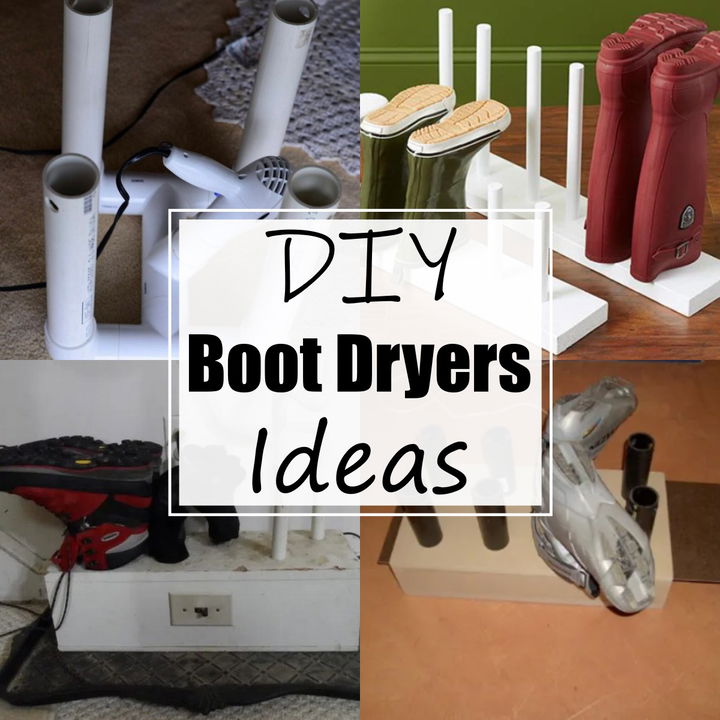

- 12 DIY Boot Dryer Ideas For Every Home Owner

- 15 DIY Drying Rack Projects For Laundry Room

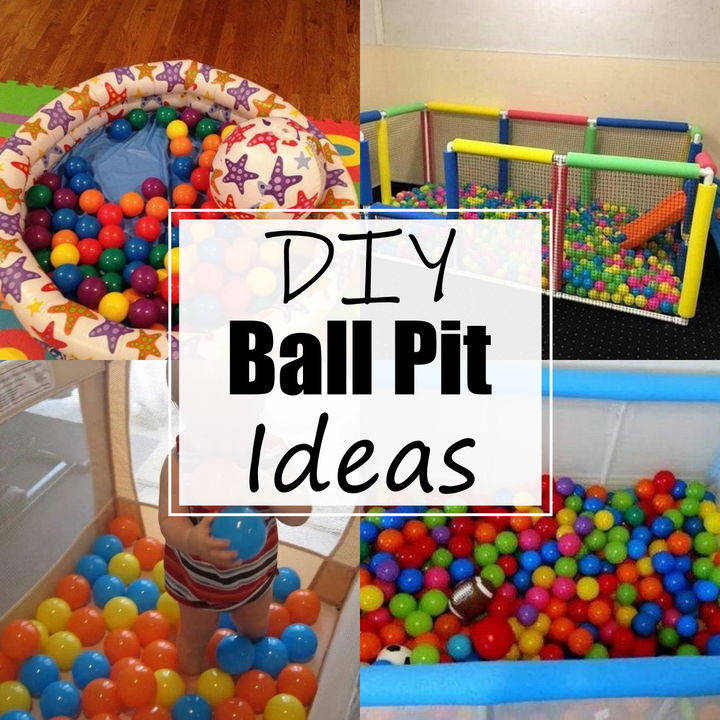

- 25 DIY Ball Pit Ideas For Toddlers

- 28 DIY Paper Towel Holder Projects For Your Bathroom

- 14 DIY Solo Stove Projects For Campers

- 11 DIY Key Holder Ideas With Cheap Materials

- 11 DIY Playpen Projects For Baby Nurseries

- 17 DIY Pool Deck Plans For Outdoor Pools

- 14 DIY Executive Desk Plans For Home Office

- 30 DIY Pipe Desk Ideas For Home Use

- 13 DIY Computer Desk Ideas For Workspace

- 19 DIY Clay Ring Ideas For Ladies

- 11 DIY Student Desk Plans Easy & Cheap

- 16 Unique DIY Macrame Shelf Ideas

- 23 DIY Crossbody Bag Sewing Patterns For Ladies

- 25 DIY Storage Cabinet Plans For Organization

- 13 DIY Pot Rack Ideas For Kitchen Organiztion

- 10 DIY Pool Waterfall Ideas For Home Decor

- 25 DIY Barefoot Sandal Ideas For Ladies

- 28 DIY Gift Bag Ideas For Birthday And Parties

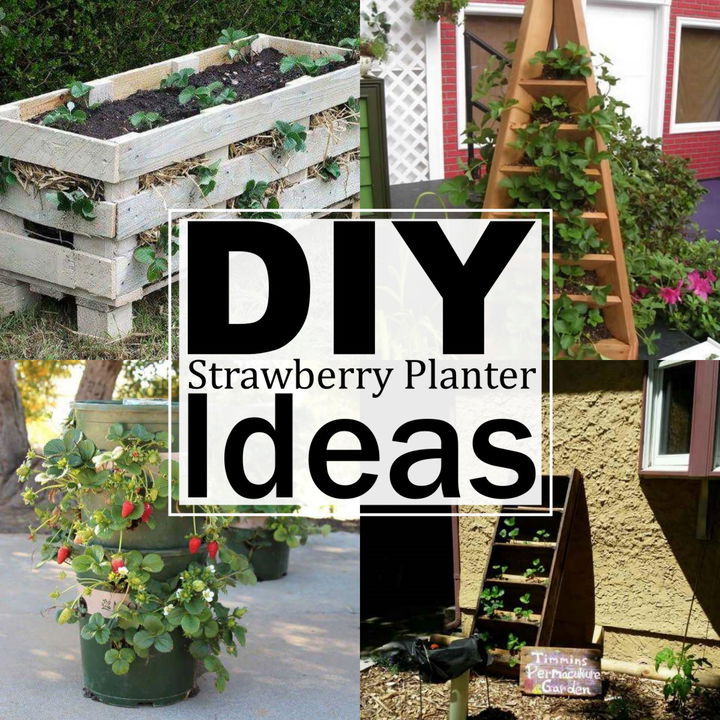

- 29 Best DIY Strawberry Planter Ideas For Home Gardening

- 20 DIY Charcuterie Board Wood Projects For Cutting And Serving

- 22 DIY Cat House Ideas Indoor & Outdoor